NEWS

-

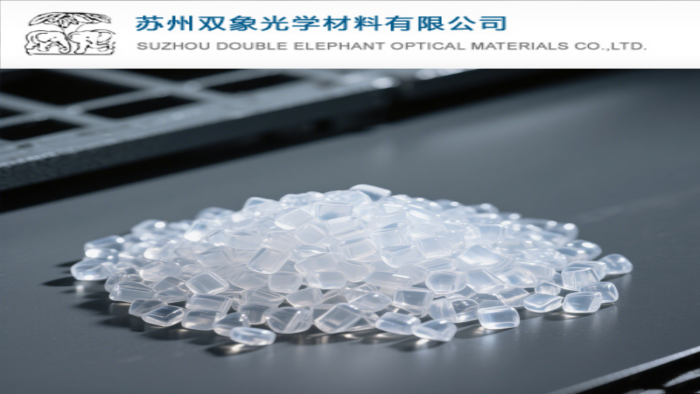

Double Elephant PMMA: Your Global Partner for Standard & Custom Acrylic Solutions

Nov 2025,08Premium PMMA Grades for Demanding ApplicationsDouble Elephant PMMA SX-306 - Superior Optical Grade* 93% light transmittance with only 0.3% haze* Excellent processing stability for injection molding* Ideal...Learn more -

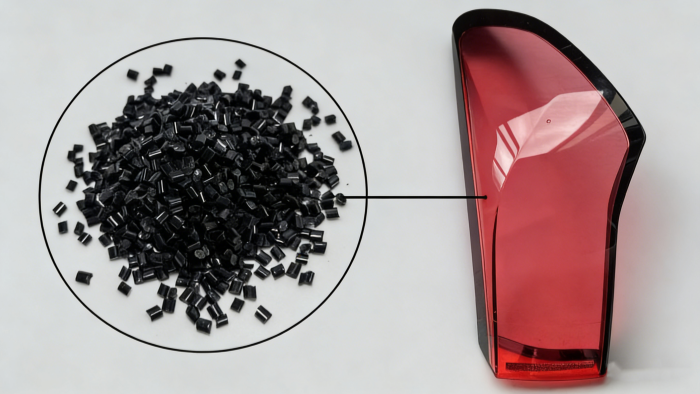

L85116MA Black Modified PMMA

Feb 2026,25/* 文章内容容器——控制全局字体、字号与行距 */ .article-content { font-family: "Times New Roman", serif; font-size: 18px; line-height: 1.65; color: #2F3E2F; /* 正文深灰略带绿调,柔和耐看 */ max-width: 100%; } /* -------...Learn more -

MS Resin Selection Guide: Wanhua vs Double Elephant – Properties, Grades Applications

Feb 2026,23/* 文章排版优化 - 新罗马字体 · 商务环保绿标题 · 18px正文 */ /* 作用域限定在当前文章块,不影响网站其他部分 */ .ds-message .ds-markdown { /* 覆盖内联样式:重置缩放,强制字体、字号、行高 */ zoom: 1 !important; font-family: "Times New Roman", Times, serif !imp...Learn more -

PA66 Carbon Fiber Modified Material for Agricultural Drones Custom Solutions by Prime Union Trade and PrimeTech Plastics

Jan 2026,19The advancement of sustainable and efficient precision agriculture is closely tied to the innovation in drone technology. At the heart of high-performance agricultural drones lies a critical factor: the materials that constitute their core ...Learn more -

Drone Airframe Material:Carbon Fiber Reinforced Nylon (PA CF) Solutions

Jan 2026,14In the rapidly evolving UAV industry,selecting the right material for the airframe is crucial for optimal performance,durability,and cost-efficiency.As drones take on more demanding roles in logistics,surveillance,agriculture,and beyond,the...Learn more -

Mitsubishi Chemical ACRYPET™ PMMA VH 001 Materia & Qingdao Prime Union Trade Co., Ltd.

Jan 2026,08ACRYPET™ PMMA VH-001Optical Grade Polymer with High Light Transmission & Stable ProcessingA material option for optical components is now available. Qingdao Prime Union Trade Co., Ltd. offers Mitsubishi Chemical's ACRYPET™ PMMA VH-0...Learn more -

Is ABS Plastic Food Grade? A Guide to Food-Safe ABS Materials & Certified Grades

Dec 2025,25Is ABS Plastic Food Grade? Your Guide to Food-Safe ABSThe use of plastics in food packaging, kitchenware, and food-contact applications is widespread. For manufacturers and designers, selecting the correct material is critical for safety an...Learn more -

Qingdao Prime Union Plastic: Authorized SABIC Material Supplier for LEXAN™ 123R-111 Polycarbonate

Dec 2025,24Material OverviewLEXAN™ 123R-111 is a high-performance polycarbonate material with balanced properties for demanding applications. With a melt flow rate of 17.5g/10min, it offers excellent flow characteristics for complex mold designs.Techn...Learn more

English

English