Modified nylon is a type of engineering plastics. It is a granular product formed by using nylon raw materials as the base material and changing its physical properties. The output of such products is modified and produced according to the different needs of some manufacturers.

Thermal properties: glass transition temperature (Tg) and melting point (Tm); high heat distortion temperature (HDT); high long-term use temperature (UL-746B); wide use temperature range; small thermal expansion coefficient.

Mechanical properties: high strength, high mechanical modulus, low latent degeneration, strong wear resistance and fatigue resistance.

Others: chemical resistance, electricity resistance, flame resistance, weather resistance, and good dimensional stability.

The output of such products is modified according to the different needs of some manufacturers. Modified nylon generally includes: reinforced nylon, toughened nylon, wear-resistant nylon, halogen-free flame-retardant nylon, conductive nylon, flame-retardant nylon etc. Modified nylon has many properties, so it is widely used in automobiles, electrical equipment, mechanical parts, transportation equipment, textiles, papermaking machinery, etc.

As the largest and most important variety of engineering plastics, nylon has strong vitality, mainly because it can be modified to achieve high performance. Secondly, industries such as automobiles, electrical appliances, communications, electronics, and machinery have increasingly higher requirements for high-performance products. The stronger the demand, the rapid development of related industries has promoted the process of high-performance engineering plastics. The future development trend of modified nylon is as follows.

The market demand for high-strength and high-rigidity nylon is increasing. New reinforcement materials such as inorganic whisker reinforcement and carbon fiber-reinforced PA will become important varieties, mainly used for automobile engine parts, mechanical parts and aviation equipment parts.

Nylon alloying will become the mainstream of the development of modified engineering plastics. Nylon alloying is an important way to achieve high performance of nylon, and it is also the main means to manufacture nylon, nylon special materials, and improve the performance of nylon. By blending other polymers, the water absorption of nylon can be improved, the dimensional stability of the product, as well as low-temperature brittleness, heat resistance and wear resistance can be improved. Therefore, it is suitable for use with different requirements of vehicle types.

The manufacturing technology and application of nano-nylon will develop rapidly. The advantage of nano-nylon is that its thermal properties, mechanical properties, flame retardancy and barrier properties are higher than those of pure nylon, while its manufacturing cost is equivalent to that of ordinary nylon. Therefore, it is very competitive.

The number of flame-retardant nylons used in electronics, electrical appliances and electrical appliances is increasing day by day, and green flame-retardant nylons are receiving more and more attention from the market.

Antistatic, conductive nylon and magnetic nylon will become the materials of choice for electronic equipment, mining machinery, and textile machinery.

The research and application of processing aids will promote the functionalization and high performance of modified nylon.

Modified nylon has good dimensional stability, high temperature resistance, easy processing, molding and demoulding. It has high mechanical strength, good toughness, and a high heat deformation temperature. After glass fiber reinforcement, the heat deformation temperature can reach more than 250 degrees Celsius. At the same time, glass fiber reinforced products with a glass fiber content of 10%-60% can be prepared according to customer needs. Therefore, it is widely used in medical, aviation, electric power equipment, mechanical equipment, shipbuilding, automobile manufacturing, household appliances, digital products, textile equipment, daily necessities, construction equipment, toys and other fields.

1.Medical field

Nylon materials have mechanical strength and skin-friendly feel that ordinary materials do not have. Medical equipment such as foot drop correctors, rehabilitation wheelchairs, and medical nursing beds usually require components with a certain load-bearing capacity, so PA66+15%GF is generally chosen.

2. Auto parts

Automotive PA66+GF materials can be used in engine intake pipes, engine hoods, automobile chassis, engine fan blades, automobile air conditioning evaporator condensers, etc.

The air intake pipe is made of PA66+30%GF, with long-term temperature resistance of 140℃ and more than 2000 hours.

Automobile chassis fenders and engine fan blades PA66+30%GF require excellent toughness and strength, as well as low deformation and dimensional stability.

Automotive air conditioner evaporator PA66+15%GF+10% talc requires good warpage, long-term heat resistance, hydrolysis resistance, high dimensional stability, high strength and toughness.

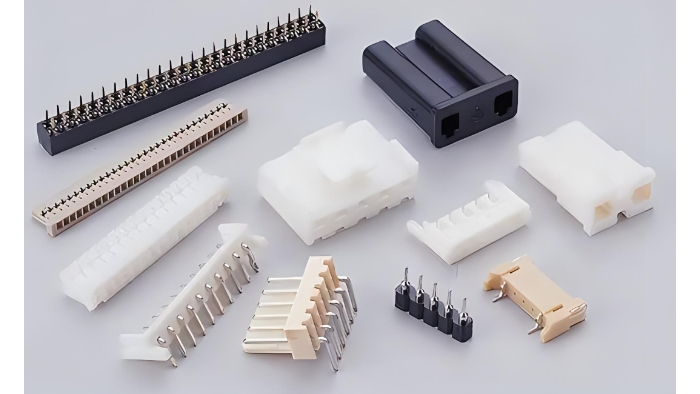

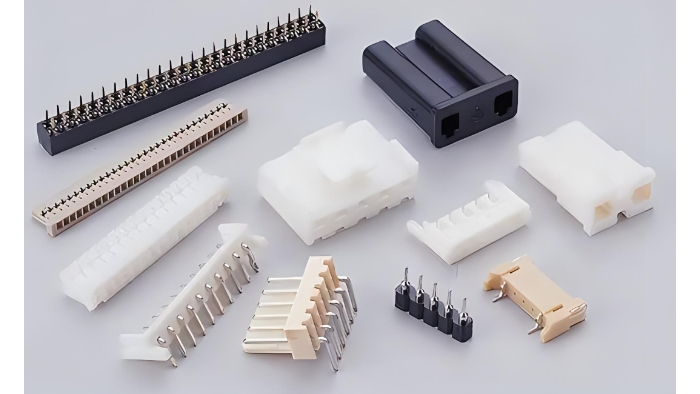

3.Various connectors for electronic accessories

This is the application field of halogen-free flame retardant PA66+35%GF and PA66+35%GF in various electronic connectors. Electronic connectors need to have high fluidity, dimensional stability, good electrical properties, and some also require flame retardant properties. At this time, only modified materials can completely replace them.

4.Various high-power fan blades and impellers

High rigidity, high toughness, low warpage, creep resistance, hydrolysis resistance modified PA66+30%GF material.

5.Various precision gears

High rigidity, dimensional stability, noise reduction, wear resistance, silent, lubrication, antistatic PA66+20%GF smooth material.

6.Tableware

High temperature resistance, food grade, high fluidity, reinforced, PA66+30%GF.

Qingdao Primetech Plastic was established in 2007 and has 17 years of experience in the production of modified plastics, dyeing and color masterbatches. Focusing on one-to-one customized development, we have a mature formula system to ensure that products can accurately meet customer needs. As a powerful modified plastics manufacturer, our products cover modified nylon, PC/ABS alloys, halogen-free flame-retardant engineering plastics, glass fiber reinforced modified materials, antistatic materials, medical grade masterbatch, etc. If you have any needs for modified engineering plastics, please feel free to call us for consultation. You can also communicate directly with customer service through online messages.

English

English