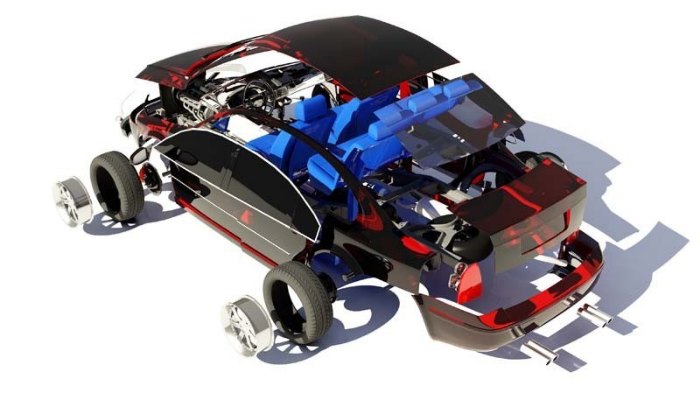

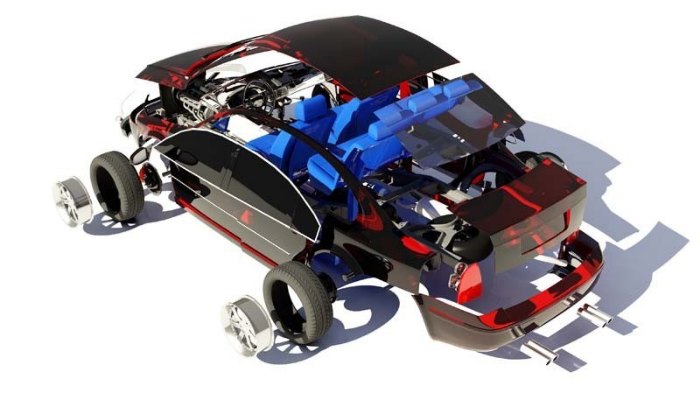

PP materials for automobiles have become an important material in the field of automobile manufacturing. With the trend of lightweight automobiles, PP materials are increasingly used in automobile interiors, exteriors, electrical appliances, etc. The following is a summary of the development trends of automotive PP materials by the editor of Qingdao Prime:

1. High performance: With the continuous advancement of automobile manufacturing technology, the performance requirements for PP materials for automobiles are also getting higher and higher. In the future, PP materials for automobiles will need to have higher strength, stiffness, heat resistance, weather resistance and other properties to meet the requirements of automobiles in extreme environments such as high temperature, low temperature and humidity.

2. High functionality: PP materials for automobiles not only need to have basic mechanical and physical properties, but also need to have some special functions, such as flame retardant, anti-ultraviolet, antistatic, conductive, etc., to meet the diversification of materials required by automobiles.

3. High environmental protection: Environmental protection is one of the development trends of future automotive materials. In the future, PP materials for automobiles need to have characteristics such as low volatility, low VOC emissions, and low toxic and harmful substances to meet environmental protection requirements.

4. High integration: With the continuous development of automobile manufacturing technology, integrated production in the automobile manufacturing process has become a future development trend. In the future, PP materials for automobiles need to have good processing properties and molding properties to achieve integrated production and save production costs.

5. High plasticity: In the future, PP materials for automobiles need to have better plasticity and fluidity to meet the needs of complex shapes such as automobile interiors and exteriors. They also need to have better surface properties to meet the requirements of automobile appearance.

To sum up, the development trend of PP materials for automobiles in the future is high performance, high functionality, high environmental protection, high integration and high plasticity. At the same time, it is also necessary to continuously promote technological innovation and industrial upgrading to meet the needs of the automobile manufacturing industry.

Hanwha TotalEnergies has developed a series of high-performance PP materials for automotive parts, including flame-retardant PP, heat-resistant PP, high-gloss PP, high-rigidity PP, etc., with rich varieties and wide applications, which can meet all the above requirements.

Qingdao Prime Trading is Hanwha TotalEnergies's northern region agent. It has been an agent for Hanwha TotalEnergies's PP materials since 2002. The materials are imported directly from South Korea. The company is registered in the Qingdao Bonded Port Zone and has the right to operate import and export operations. It can conduct intra-area re-export trade, customs manual trade (customs supervision), US dollar general trade, etc. There are 4 self-owned warehouses with sufficient supply. At the same time, the sister company Qingdao Prime Plastic is a senior modification factory with 15 years of experience and can provide one-stop service for plastic modification, dyeing, and injection molding process support. If you have any needs for PP materials for automotive use from Hanwha TotalEnergies, please feel free to call us or leave a message/communicate online.

English

English