The coefficient of linear expansion (CLTE) is an important parameter for the dimensional stability of automotive polypropylene (PP) materials. Generally, the CLTE of PP materials is relatively large, and the CLTE in the melt flow (MD) direction and the vertical flow (TD) direction are very different during injection molding. The TD direction is almost 2 to 3 times that of the MD direction, which cannot meet the needs of automotive parts. Dimensional stability requirements.

Reducing the CLTE of PP materials and improving their dimensional stability can reduce mismatches and assembly gaps with other assemblies and improve assembly effects.

What is CLTE?

CLTE refers to the ratio of the change in length (ΔL) of the material within the range of unit temperature change (ΔT) to the initial length (L). CLTE=ΔL/(L×ΔT). The CLTE of the material is closely related to the size of the material, which will affect the assembly of material parts and the dimensional stability after assembly. CLTE is measured by static thermomechanical analysis (TMA). TMA measures the relationship between deformation and temperature of a material under non-vibration load under programmed temperature control. The obtained curve is a curve with the length L or deformation amount ΔL of the sample as the ordinate and the temperature T as the abscissa.

The influence of PP resin

PP is a semi-crystalline polymer with a certain degree of crystallinity, and during the injection molding process, the molecular chains will be oriented along the direction of melt flow. PP amorphous chain segments have higher mobility than crystalline segments, resulting in higher thermal expansion properties. Therefore, improving the crystallinity and molecular chain orientation of PP materials can reduce the CLTE of the material.

Effect of elastomer tougheners

Automotive PP materials usually have high toughness, but PP itself has poor toughness and needs to be toughened and modified by adding elastomer toughening agents. Commonly used elastomer tougheners mainly include ethylene propylene diene rubber (EPDM), ethylene-α olefin elastomer (POE) and styrenic thermoplastic elastomers.

1.Influence of elastomer form

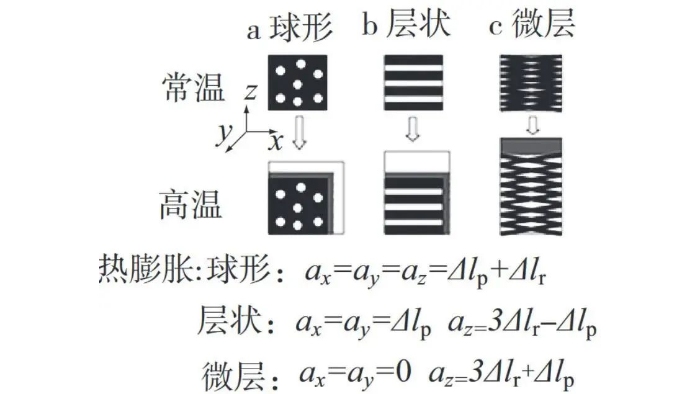

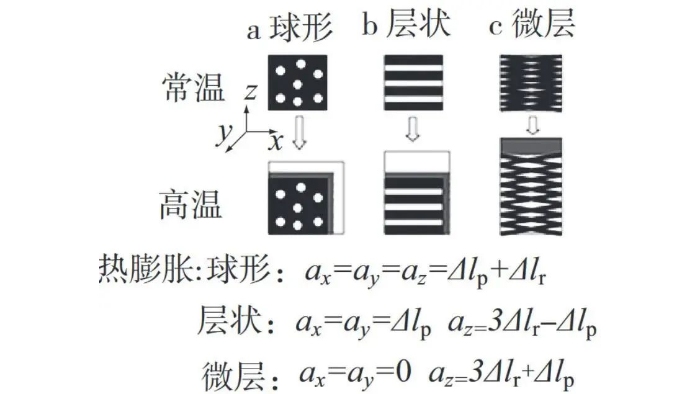

The morphology of the elastomer rubber phase has a great influence on the CLTE of PP composites. The schematic diagram of the thermal expansion behavior of plastic/rubber blends with different rubber forms is shown in the figure below.

(αx, αy and αz are the thermal expansion in the x, y and z directions respectively, Δlp and Δlr are the thermal expansion per unit of plastic and rubber respectively)

In the figure, the rubber phase a is distributed in the plastic matrix in a spherical structure. The CLTE of this system is the same in the three directions of x, y, and z, and is the sum of the CLTE of the plastic phase and the rubber phase.

In the figure b, plastic and rubber are superimposed and distributed in a thin layer structure. Since the tensile elastic modulus of plastic is 50 to 1000 times higher than that of rubber, the thermal expansion of rubber parallel to the layered direction is affected by the plastic. suppression, so the CLTE in the xy direction parallel to the layered structure decreases to that of the plastic, while the rubber will thermally expand in the direction perpendicular to the layering, causing the CLTE in the thickness direction (z direction) to become larger.

In the figure c, the rubber phase changes into a microlayer structure and forms a bicontinuous phase with the plastic matrix. The thermal expansion of the rubber in the x and y directions is highly inhibited by the plastic. The rubber expands thermally along the z direction. The expansion of the rubber will have an impact on the continuous phase plastic. Applying a tensile force in the z direction causes the plastic to expand in the z direction, further reducing the CLTE in the x and y directions.

The morphology of the elastomer mainly depends on the viscosity ratio of the elastomer/PP matrix. When the elastomer/PP viscosity ratio is low, the elastomer is rod-shaped along the MD and TD directions, and the PP is crystallized perpendicular to the elastomer direction. When the elastomer/PP viscosity ratio is medium, the elastomer becomes rod-shaped along the MD direction and spherical along the TD direction. In the MD direction, PP is oriented and crystallized perpendicular to the elastomer direction. In the TD direction, PP penetrates the elastomer randomly. Crystal orientation is reduced.

When the elastomer/PP viscosity ratio is large, the elastomer becomes circular in both MD and TD directions, indicating that the elastomer is spherical, PP penetrates the elastomer randomly, and the crystal orientation is further reduced. As the elastomer/PP viscosity ratio increases, the CLTE in the MD and TD directions increases and decreases in the thickness direction.

2. Influence of elastomer content

In addition to the morphology of the elastomer, the content of the elastomer also has a great impact on the CLTE of PP materials.

The CLTE of PP/ethylene propylene rubber (EPR) alloy increases slowly when the EPR content is less than 20%, and then decreases significantly. When the EPR content is higher than 70%, PP and EPR undergo phase inversion, and because the CLTE of EPR is smaller than that of PP large, so the CLTE of PP/EPR alloy increases rapidly.When the elastomer EPR content is 60%, the CLTE of PP/EPR alloy is 4.3×10–5°C–1, which is lower than that of 30% talc filling (5.0×10–5°C–1). Glass fiber filling (3.5×10–5°C–1) is equivalent. Therefore, the CLTE of the material can be reduced without high filler content, allowing it to be used in low-density materials.

POE is produced by polymerizing ethylene and comonomers. The content and type of comonomer in POE will also affect the CLTE of PP materials. PP and elastomers are usually incompatible and phase separation will occur. When the comonomer content is high, phase separation is slow; when the comonomer content is low, phase separation is fast. For POE with low comonomer content (9%), since phase separation is faster than PP crystallization, the PP amorphous chain will diffuse into the PP crystals, and the thermal expansion of the elastomer and PP amorphous chain segment will be less inhibited, resulting in CLTE. larger. Therefore, the CLTE of PP materials decreases as the comonomer content in POE elastomer increases.

In addition, the melt fluidity of POE also has a great influence on the CLTE of PP. As the melt flow rate (MFR) of POE increases, it becomes easier for POE to disperse to form a continuously distributed microscopic phase during the shear dispersion process of blend materials. Structure, the dispersed rubber phase is bound by PP, so that the thermal expansion behavior of the PP material in the MD and TD directions is suppressed, so the CLTE of the PP material gradually becomes smaller.

Effect of fillers(TD)

In order to improve the rigidity of PP materials, inorganic fillers are often added for reinforcement modification. Commonly used reinforcing fillers mainly include flaky talc powder and mica; needle-shaped whiskers, wollastonite and glass fiber with a certain aspect ratio; spherical calcium carbonate, etc. Among them, talc powder is the largest amount of reinforcing filler. The CLTE of these commonly used inorganic fillers is very low, so adding these inorganic fillers can significantly reduce the CLTE of the polymer material.

Among them, reducing the talc particle size and thickening the talc content can reduce the CLTE of PP in both MD and TD directions.

In order to improve the interfacial bonding force between the filler and PP, maleic anhydride grafted PP (PP-g-MAH) can be added as a compatibilizer to entangle the polymer chains with each other and interpenetrate with the filler. Thermal movement is suppressed, thereby reducing the CLTE of the PP material, and the degree of reduction is greater in the vertical flow direction.

Effect of additives

In modified PP materials, nucleating agents are often added to improve the crystallinity of the material and thereby improve the rigidity of the material. The movement of polymer chains in the crystalline region is greater than that in the amorphous region, and the degree of thermal expansion is also lower. Therefore, the PP material with nucleating agent added has higher crystallinity and its CLTE is lower than that of PP material with nucleating agent added.

Summarize

PP resin, elastomer, filler and nucleating agent have a greater impact on CLTE. Summarizing the above methods, the following conclusions can be drawn:

1.Improving the crystallinity and molecular chain orientation of PP resin can reduce CLTE.

2.Increasing the comonomer content of the elastomer, reducing the degree of phase separation, increasing the MFR of the elastomer, reducing its particle size, and adjusting the morphology of the elastomer to form a bicontinuous phase structure with the PP matrix can all reduce CLTE.

3.Adding inorganic fillers with different structures can significantly reduce CLTE.

4.Adding nucleating agents can improve the crystallinity of PP and reduce CLTE.

If you have any questions about automotive engineering plastics that need to be solved, please contact us Qingdao prime union Trading Co., Ltd.

QINGDAO PRIME TRADE CO., LTD is a company with more than 20 years of experience that specializes in distributing international brand engineering plastic particles. It mainly represents: Chimei ABS, HANWHA TOTAL PP, SABIC PPO, and PC special materials. We also have our own modified plastic factory, Qingdao primetech Plastic Co., Ltd., with a professional technical team to provide you with fast and professional services to meet the needs of customers at different levels.

English

English