As a new type of plastic pipe, PPR pipe has excellent long-term hydrostatic pressure resistance and thermal stability. PPR pipe is widely recognized in the field of building water supply, and its technical application is very mature. However, PPR pipes also have shortcomings during use: the thermal expansion coefficient is large at a high temperature of 95°C, the notch impact strength is not high, and especially the impact performance at low temperatures does not meet higher requirements. In addition, during the construction process and transportation process, due to the operator's irregular behavior, this will lead to premature damage to the pipe.So how to solve these problems?

We consulted the technical staff of South Korea's Hyosung, an excellent brand in the field of PPR pipes, with these questions. According to the current needs of customers: improve the pressure-bearing capacity and creep resistance time, heat deformation temperature and low-temperature impact resistance of PPR pipes. . South Korea's Hyosung has upgraded its products and launched a new product - PP-RCT for water supply pipes and fittings.

what's PP-RCT?

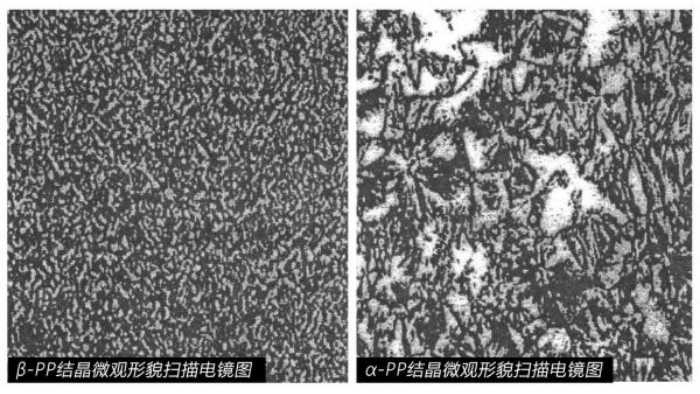

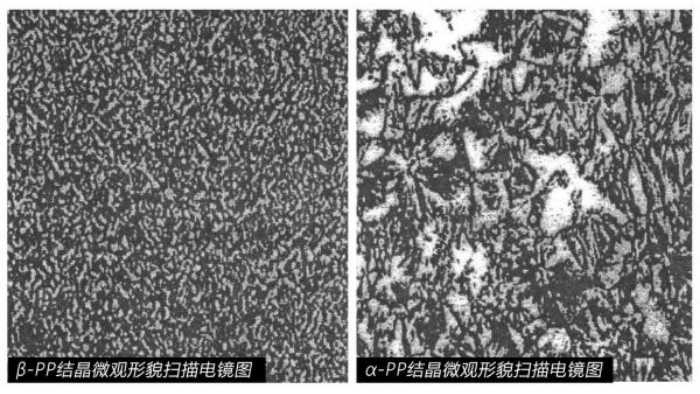

PP-RCT, the full name is Poly Propylene Random Crystallinity Temperature, also known as high-temperature resistant β-crystal polypropylene. It is an improved new generation of polypropylene material. It uses a hexagonal crystal form to replace the monoclinic form of PP-R.

After many experiments on upgrading and improving PP-R, it was found that if the side lengths of the quadrilaterals on the side of the PP-R molecule are equal and the angle is 120°, the same random copolymerization can form a hexagonal β crystal. This molecule The structure will greatly improve the disadvantages of PPR pipelines and show performance beyond PPR.

PP-RCT has a good balance of rigidity and toughness and a long creep resistance time (no inflection point in the long-term hydrostatic test curve); compared with PP-R materials, PP-RCT’s long-term strength at high temperatures is increased by more than 50%. As a result, the pipe wall can be made thinner, high extrusion speed can be used and the amount of material can be reduced to improve efficiency; or pipes with a larger inner diameter can be made to increase the volume capacity of the pipe, providing a solution to the problem of low water pressure water supply solution.

Comparison of PPR and PP-RCT

The picture below is the physical property table of Korea Hyosung PP-RCT material R202P:

| PROPERTIES | TEST METHOD | VALUE | UNIT |

| Melt Index(230℃,2.16kg) | ASTM D1238 | 0.22 | g/10min |

| Density | ASTM D792 | 0.9 | g/cm3 |

| Tensile Strength at Yield | ASTM D638 | 290 | kg/cm2 |

| Flexural Modulus | ASTM D790 | 9800 | kg/cm2 |

| Izod Impact Strength Notched at 23℃ | ASTM D256 | NB | kg-cm/cm |

| Izod Impact Strength Notched at-10℃ | ASTM D256 | 5.5 | kg-cm/cm |

| Rocewell Hardness | ASTM D785 | 75 |

|

| Heat Deflection Temperature(0.45Mpa) | ASTM D648 | 85 | ℃ |

The data shows that PP-RCT has obvious advantages in performance values such as melt flow rate, melting range, and impact strength.

1.The melting range of PP-RCT (200-240℃) is higher than the melting range of PP-R (210-220℃). The high melting range indicates that the melting of PP-RCT requires higher temperatures. It shows that PP-RCT has better high temperature deformation resistance than PP-R.

2.The melt flow rate of PP-RCT (0.22g/10min) is lower than the melt flow rate of PP-R (0.3g/10min). The low melt flow rate indicates that PP-RCT has a stronger ability to maintain its original shape after melting. This shows that PP-RCT has better resistance to high temperature deformation than PP-R.

3. The notched impact strength of PP-RCT has been greatly improved compared to PP-R, which shows that compared with PP-R, the low-temperature brittleness of PP-RCT has been greatly improved.

Advantages of PP-RCT pipes

The advantages of "PP-RCT pipe" made of a new generation of polypropylene material are reflected in the following aspects:

1.Compared with PP-R (CRS of 3.3 MPa), the CRS (5.0 MPa) is higher, and the same size pipe can withstand greater pressure at high temperatures or handle the same with a smaller inner or outer diameter. pressure.

2. The pipeline MRS value reaches 11.2 MPa.

3.PP-RCT has better oxidation resistance and slow crack growth resistance. Under the same conditions, the service life of the pipeline is greatly improved;

4.Pipes have better toughness and low temperature brittleness is significantly improved.

5.The wall thickness of water pipes can be thinner, but at the same time the flow rate of water pipes can be greater. To obtain the same flow rate, a smaller pipe diameter can be used;

6.Lighter piping system, better welding performance, easier and faster installation.

7.It reduces the use of raw materials and contributes to the conservation of non-renewable resources and the sustainable development of the environment.

Currently, many pipe manufacturers from European countries are using the new material PP-RCT to manufacture water supply pipes and fittings. In high-end pipe systems such as hot and cold water supply and heating, manufacturers using PP-RCT materials have outstanding advantages. Compared with ordinary PP-R pipes, their PP-RCT pipes have increased their long-term strength by more than 50% and have a longer service life after 50 years at 70°C.

If you are also interested in Hyosung Korea's PP-RCT products, please contact us for more information.

Qingdao PRIME UNION Trading Co., Ltd. has specialized in representing international brand engineering plastics such as Chimei ABS, HANWHA TOTALENERGIES PP, SABIC PPO and special materials, and South Korea's Hyosung PPR for 20 years. It has won customers with its professional knowledge and high-quality services. trust and support.

English

English