As we all know, many car accessories are often made of metal + plastic, wood + plastic, metal + wood + plastic. If their CLTE values are very different and the thermal expansion and contraction ratios are different, even if there are no problems with the parts at the beginning, the parts will be affected by temperature changes later and cracks will occur. Then when choosing plastic materials, the CLTE value of the plastic material is extremely important. So today we will analyze for you, which plastics are more suitable for the automotive industry? What scenarios are modified plastics with different CLTE values suitable for?

Among the mainstream plastic substrates, which one is more suitable for making auto parts?

Question: What are the consequences of using plastics and metal/wood materials with inappropriate CLTE values directly in auto parts?

As an example:

Assume that the length of the spoiler made of PC/ABS is 1000mm, and the CLTE of PC/ABS is 7-8*10-5K-1. When the body temperature changes in winter and summer/morning and evening exceeds 50℃, its theoretical size change rate reaches AL= The CLTE of 3.5-4mm metal is generally below 10*10-K-1, which is quite different from plastic. The expansion ratios of body plastic and sheet metal are different. When the temperature difference is large, it is easy to occur:

1. Zero gap during design, use Later, a large gap/surface difference appeared;

2. Parts are deformed or even cracked;

3. Risk of abnormal noise caused by dimensional changes

All in all, countless failure cases have proven that when the CLTE value of plastic materials is different from that of metal materials/wood-plastic materials, there are many problems and increased production costs.

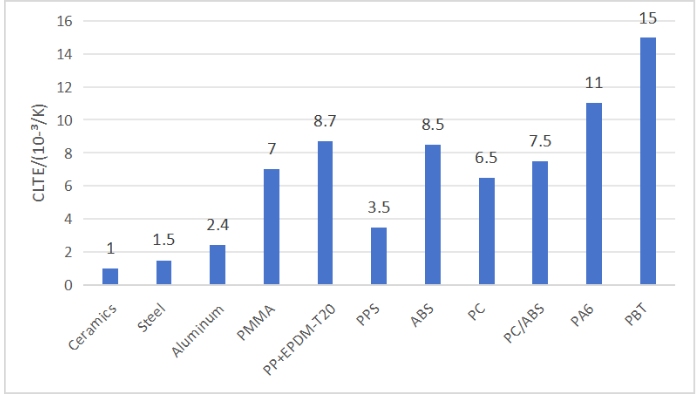

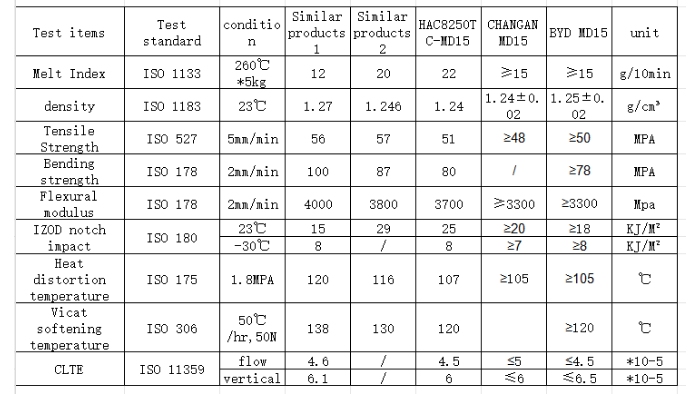

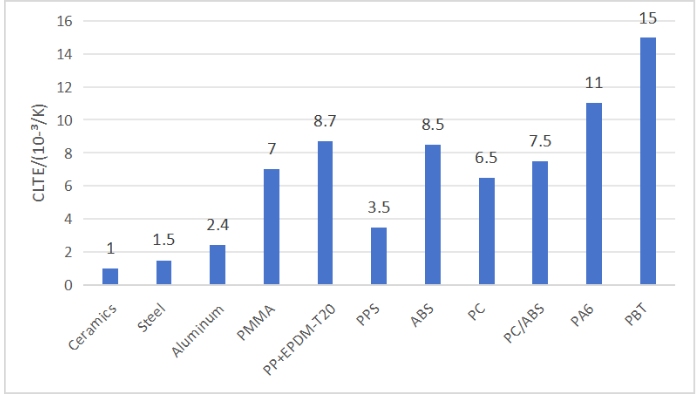

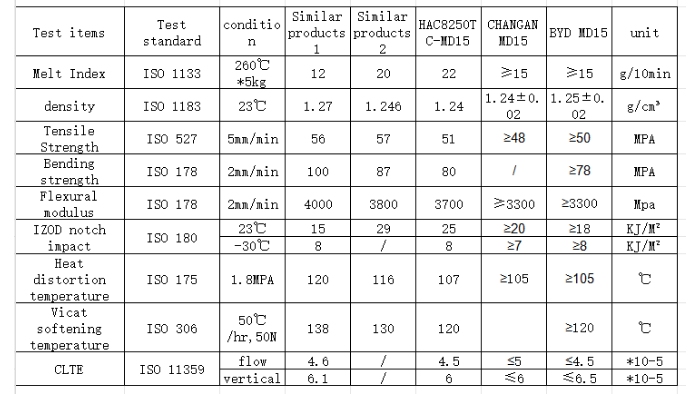

So, which plastic substrates have CLTE values closer to metals? Let's look at a set of data:

From the data in the table, we can clearly see that PPS has the upper hand due to its excellent low CLTE value. So can PPS be used to solve the problem of dimensional deformation? People in the plastics industry know that although PPS is suitable for insert injection molding with metal, the toughness of PPS is too poor, and the notch impact is ≤3 (generally PPS must be filled with mineral powder + glass fiber to ensure basic performance requirements); moreover, the price of PPS is also Too high, it can be called the "Hermès" of low expansion coefficient products. Therefore, although the CLTE value of PPS is satisfactory, the price is too high and the impact strength is poor.

What about other plastic materials? The difference in their CLTE values is still very large, but it is also regular.

The CLTE value of plastics is much higher than that of inorganic materials (metals..);

The CLTE of crystalline materials (PA, PP, PBT) is generally higher than that of amorphous materials (PC, PC/ABS, ABS);

Amorphous materials generally have higher heat resistance, lower CLTE, and more stable dimensions.

According to this rule, we can conclude that amorphous materials are more suitable than crystalline materials, especially the highly heat-resistant amorphous material - PC. However, the CLTE value of PC is as high as 6.5, which is much higher than that of metal 1.5. It seems that dimensional stability is difficult to achieve. So what good suggestions do our engineers have?

If we want to achieve high dimensional stability of parts, there are generally two ways to achieve it: structure and material.

①Material: Add glass fiber or mineral powder to obtain low CLTE material;

②Structural design: We reduce the problem of large overall deformation due to large size of parts.

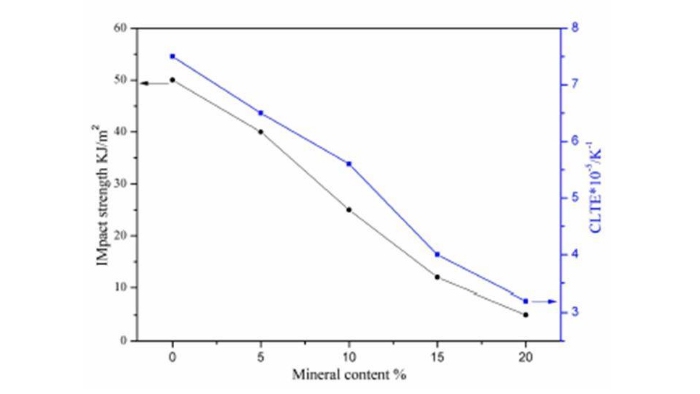

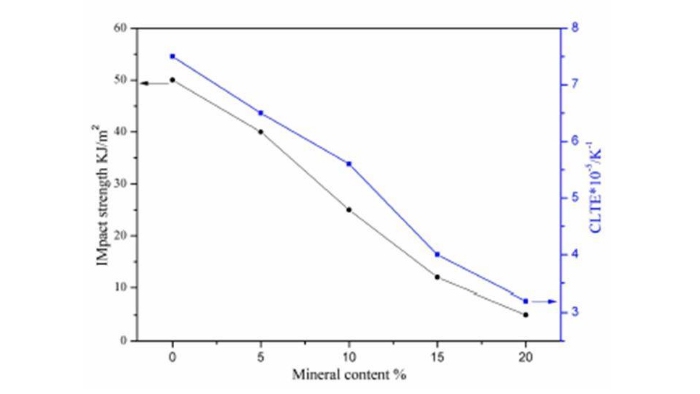

However, adding glass fiber will bring about two fatal bugs (warping deformation; floating fiber problem, inability to spray paint), which will undoubtedly increase the cost of more scrap parts; while adding mineral powder, although it also has disadvantages: reduced toughness, processing Narrow window; advantages are high design freedom;increased strength; good dimensional stability; high heat resistance. The advantages obviously outweigh the disadvantages, and the disadvantages can also be improved. Although the toughness has declined, it can still meet the basic impact requirements of automobiles; the narrow processing window can be solved through mold design and process adjustment. The current solution is to modify PC materials with ore powder filling to produce low CLTE materials.

What are the applicable scenarios for base materials with different CLTE values?

In the previous content, we have studied how to obtain products with low CLTE values by filling mineral powder into PC materials. So is it true that the more mineral powder is filled, the lower the CLTE value of the plastic is, the better? The answer is not like this. Because we found that the more mineral filling, the lower the CLTE value, and at the same time, the toughness will also decrease.Therefore, it is not advisable to overfill mineral powder to reduce CLTE. In particular, many large, slender, integrated parts with high dimensional accuracy requirements in the automotive industry require not only high dimensional stability, but also certain mechanical properties and processability.

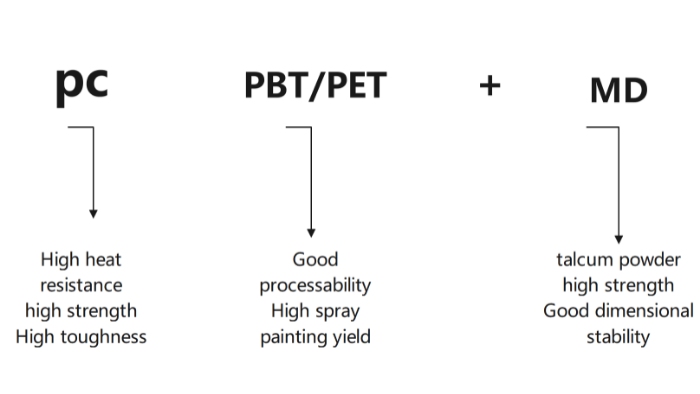

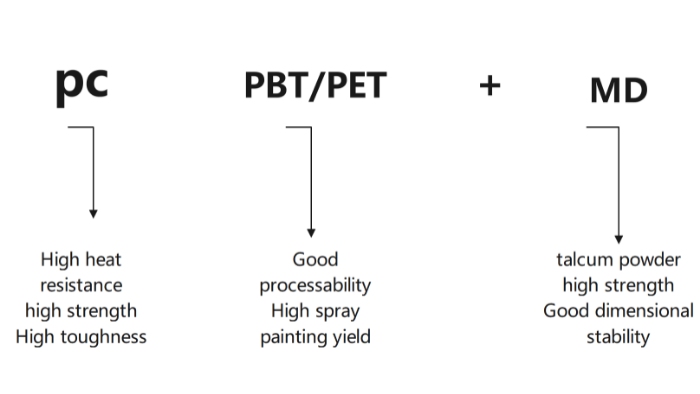

Based on this premise, we carried out base material blending, mineral filling and other modifications on the basis of PC, and obtained these two low CLTE materials: PC/ABS-MD and PC/polyester-MD.

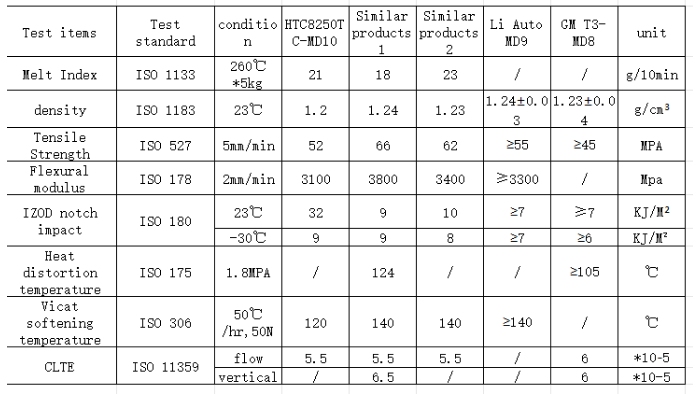

We will take Kumho Sunny modified plastics as an example to see how effective these two low CLTE materials are?

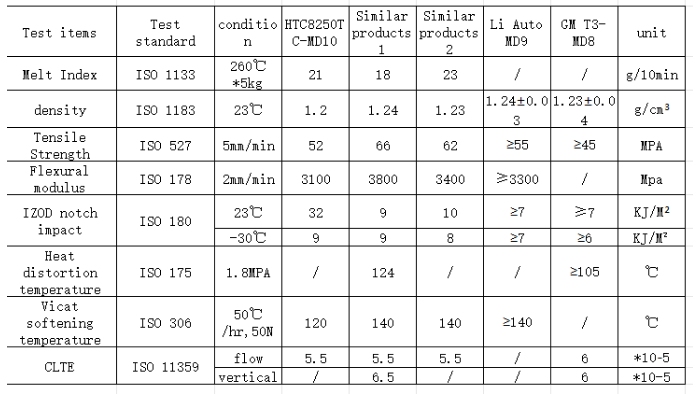

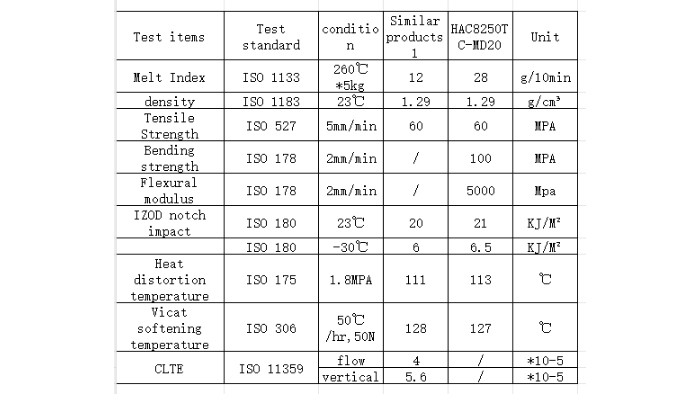

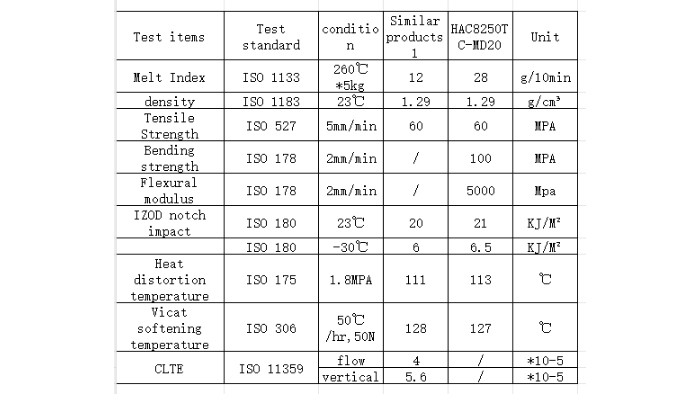

The first low CLTE material: PC/ABS-MD

Let us first take a look at the physical property tables and applications of PC/ABS materials with different mineral contents:

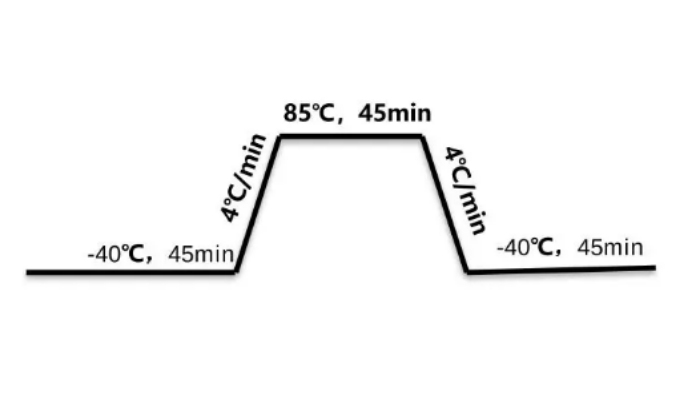

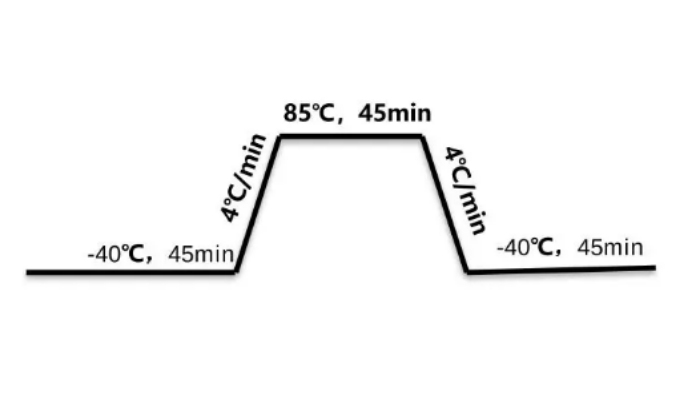

At present, dual screens in automobiles are a popular trend. We all know that single screen frames are generally made of PC/ABS material, but for dual screens, ordinary PC/ABS is used as the frame,and frames often appear in hot and cold cycle experiments. The display is cracked or crushed. But PC/ABS-MD10 effectively solves this problem:

PC/ABS-MD10 has good appearance and good paintability;

PC/ABS-MD10 has good toughness and there are many buckles behind the display frame structure;

PC/ABS-MD10 has good rigidity, and some screen brackets are hollow structures;

PC/ABS-MD10 can also successfully pass the 1524h hot and cold cycle test without cracking.

PC/ABS-MD10 is usually used in scenarios with higher toughness requirements, such as car charging piles (which can solve dimensional problems after assembly, conventional materials spray paint cracking, materials with good thermal stability,etc.); sunroof trim rings and decorations Materials used for plate and platform parts (solve the problem of deformation under high and low temperatures)

PC/ABS-MD15, the CLTE value is relatively low. As the density increases, it also loses part of the notch impact force, but it can still meet the basic impact requirements of the car. Therefore, in automotive projects, PC/ABS-MD15 The usual role is to avoid direct collision parts, but for long parts with high dimensional stability requirements.For example: tailgate trim panels, luggage brackets, radome covers, car rear wings, car ceiling light decorative covers and sealing plates, etc.

In summary, PC/ABS-MD is a low-CLTE material with good appearance and good toughness. The rigidity can be customized according to the filling amount, and it can solve the dimensional problem caused by low mold opening shrinkage.

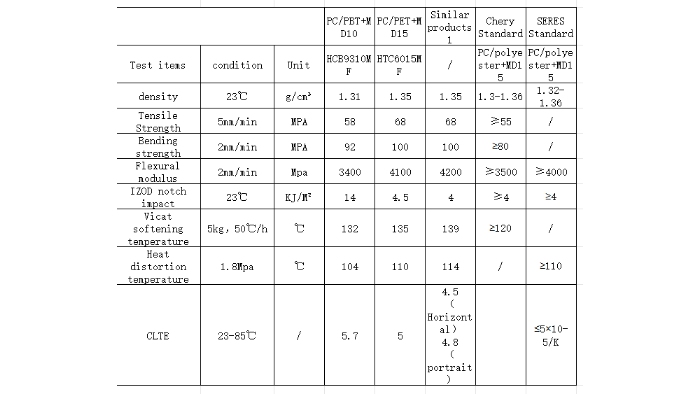

The second low CLTE material: PC/polyester-MD

Next we will look at the performance of PC/polyester-MD? What are its advantages?

PC has poor fluidity and is easily degraded when exposed to alkali, and talc powder (Talc) is alkaline (PH=8-10). PC and polyester (PBT/PET) are prone to transesterification, and extrusion reactions are difficult to control. question. Therefore, under the premise of PC/polyester instability, if you want to obtain a high-performance PC/polyester-MD, you must put forward higher requirements for the product materials and manufacturing process. So, are there any successful cases so far? Of course there is, refer to Kumho Sunny’s PC/polyester-MD.

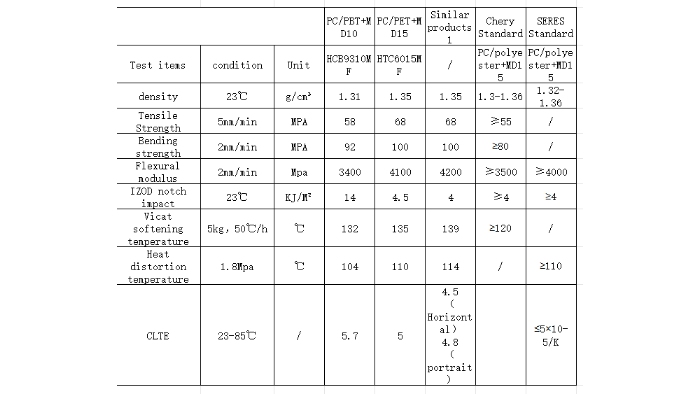

Compared with PC/ABS-MD, PC/polyester-MD has more advantages in rigidity and heat resistance.

PC/PBT+MD10, more impact resistant, applicable scenarios include: refueling/charging covers, door handles, etc.

PC/PET+MD15 has superior toughness and rigidity, and is more resistant to deformation. It is more suitable for scenes such as car tail fins and top-mounted lidar covers.

PC/ABS-MD,PC/PBT-MD,PC/PET-MD CLTE is same,so which we will choose?

In terms of cost, due to the instability of the PC/polyester system, the cost in the formula design process is higher than that of PC/ABS+MD.

In terms of performance, due to the presence of polyester, the PC/polyester+MD system has higher dimensional stability, better painting yield, and is more suitable for thin-walled design (equal parts) compared to PC/ABS+MD. Mineral filling, higher modulus), it is widely used in mid-to-high-end models.

In terms of processability, PC/ABS+MD has advantages, but PC/polyester+MD, which masters scientific formulas and processes, is also equally powerful.

If you are also troubled by the problem of low CLTE PC alloy materials, please feel free to consult Qingdao Prime union about Kumho Sunny low CLTE PC alloy.

QINGDAO PRIME TRADE CO., LTD is a company with more than 20 years of experience that specializes in distributing international brand engineering plastic particles. It mainly represents: CHIMEI ABS, HANWHA TOTAL PP, SABIC PPO, PC special materials, and Kumho Sunny. We also have our own modification processing factory, Qingdao Primetech Plastic Co., Ltd., with a professional technical team to provide you with fast and professional services to meet the needs of customers at different levels.

English

English