Foreword:

Railway transportation, which extends in all directions, has become the main way for us to work and travel. A wonderful journey experience is inseparable from clean and bright carriages, fresh air and a comfortable and safe environment. Now, SABIC innovative materials are adding a bright and environmentally friendly green color to rail travel.

The crowds in the train carriages are dense and closed for a long time, which determines that the interior materials of the carriages must meet more stringent technical requirements for flame retardant and fire safety. At the same time, heat, smoke density and toxic gas indicators need to be minimized to ensure the health and safety of passengers.

SABIC LNP ELCRES FST series copolymers are injection moldable or extrusion-resistant products with flame spread resistance, low smoke and non-toxicity (FST) properties. It not only complies with the requirements of the European rail transit fire safety standard EN45545 R1-HL2, which is recognized by the industry as a "potential global standard", but also meets the core needs of rail transit original equipment manufacturers (OEMs). It is an ideal choice for passenger trains, subways and Ideal material for wall panels and ceilings specifically designed for rail vehicles such as trams.

Sabic has researched and produced four new LNP ELCRES FST copolymer resins that comply with the European railway standard EN45545 R6-HL 2 and can be used for rail train seats.

Designers can benefit from these new material solutions that not only meet new regulatory requirements but also provide greater opportunities to create stylish seating designs. Compared with thermosetting resins and aluminum materials, the new ELCRES resin is lighter in weight and more efficient in processing, eliminating the need for secondary processing.

To achieve a seamless aesthetic appearance in one-piece seating units or designs with separate back shells, Sabic offers precise color matching for its extrusion grade (LNP ELCRES FST2732E resin) and injection molding grade (LNP ELCRES FST2432 resin) . For customers requiring a more sustainable solution, Sabic offers bio-based versions of each grade.

"Since the EN45545 standard came into effect, the rail industry has faced challenges in obtaining thermoplastic materials that meet the requirements - Sabic has been proactive in providing solutions. With our new With LNP ELCRES FST products, we not only meet our customers' high expectations for compliance, performance, aesthetics and manufacturability, but we also meet their sustainability goals with bio-based versions available in a variety of grades, Manufacturers can once again take advantage of the benefits of thermoplastics in their seating applications.”

Bio-based materials improve sustainability

The bio-based versions of extrusion- and injection-molding grades developed by Sabic are intended to extend the sustainability benefits of LNP ELCRES FST beyond the elimination of paint and weight savings. The LNP ELCRES FST2732EB (extrusion) and LNP ELCRES FST2432B (injection molding) products use 55% renewable raw materials derived from crude tall oil and other waste materials.

Both are potential drop-in solutions with the same high performance and compliance as fossil grade. Intergovernmental Panel on Climate Change (IPCC) carbon dioxide (CO2) equivalent analysis shows that these bio-based products produce 33% less carbon emissions compared to fossil-based products.

Customized colors and chemical resistance enhance aesthetics

The new LNP ELCRES FST copolymer offers a wide range of molded color options, including custom colors, to help OEMs and rail operators brand their seats as part of the interior. Molded colors eliminate the need for secondary painting, reducing costs and CO2 emissions.

To maintain the attractive appearance of rail train seats throughout their service life, Sabic materials offer excellent chemical resistance to simplify graffiti removal and a good balance of stiffness and impact resistance for increased durability performance and extend service life. Additionally, the increased stiffness of LNP ELCRES FST grades compared to standard PC allows the same part to be manufactured using less material, resulting in cost savings.We've taken this important development effort one step further by formulating inlays for both grades. The bio-based version provides the industry with a new option to improve the sustainability of rail train seats. "

If you are interested in rail transit PC resin, please contact us Qingdao Prime Union Trading Co., Ltd.!

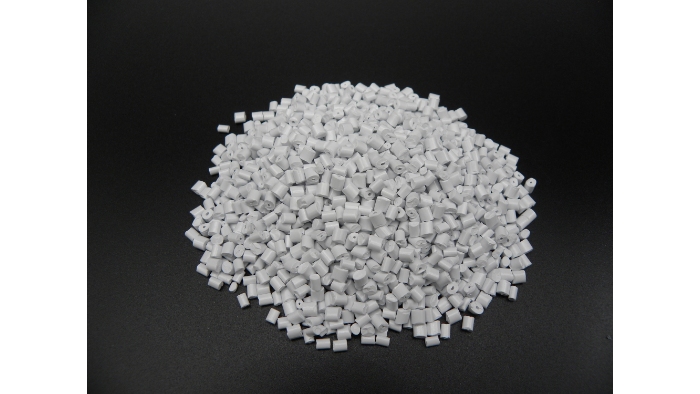

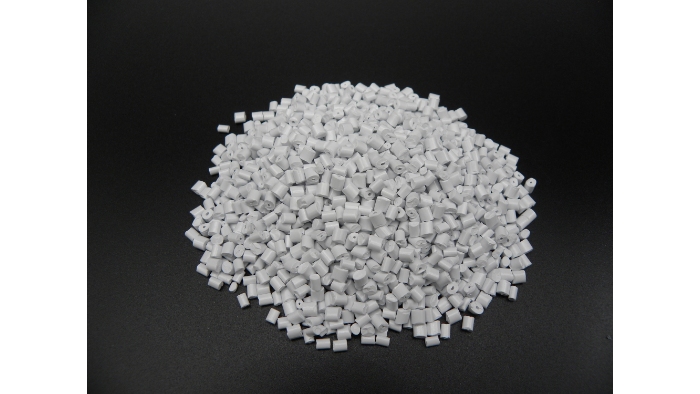

In addition, not only SABIC LNP ELCRES FST copolymer resins can be used in rail transit,CHIMEI PC-616LS is an opaque flame-retardant PC material. Its flame-retardant grade can reach UL94 1.0mm V0 grade and oxygen index 38.3. The flame retardant performance, smoke toxicity, smoke density, etc. have all passed the national standard TB/T flame retardant technical conditions for interior decoration materials for EMUs, and the EU's EN45545_R22 fire retardant standard for rail vehicle small parts interior decoration materials, and UL2043 visible smoke release fire protection Testing and other standards requirements. Currently, it is widely used in CRRC high-speed rail and other projects.

QINGDAO PRIME TRADE CO., LTD is a company with more than 20 years of experience that specializes in agenting international brand engineering plastic particles. It mainly agents: CHIMEI ABS, HANWHA TOTAL PP, SABIC PPO, PC special materials.We also have our own modified processing factory, Qingdao Primetech Plastic Co., Ltd. (for modified plastics, please learn: https://www.qdprime.com/customized-service.html), with a professional technical team to provide you with fast and professional services to meet the needs of customers at different levels. For details please consult:https://www.qdprime.com/

English

English